Energy and drive solutions for upstream and midstream in the oil and gas industry

Tailored turnkey solutions for onshore and offshore resource extraction

Our complete drive and energy solutions for upstream and midstream processes provide maximum efficiency and reliability at every stage of oil and gas production. From drilling to production and gas compression, our tailored systems ensure smooth operation under the most demanding conditions. With advanced technology, high flexibility, and maximum energy efficiency, we ensure that your facilities operate optimally and safely at all times – even in the most remote regions. Rely on powerful and sustainable drive solutions and comprehensive services that are perfectly tailored to your needs.

Available for you 24/7

Germany

International

Zeppelin Power Systems Solutions for Oil & Gas

Our holistic solutions for your drilling projects at a glance

Key benefits for your organization

Premium quality with service

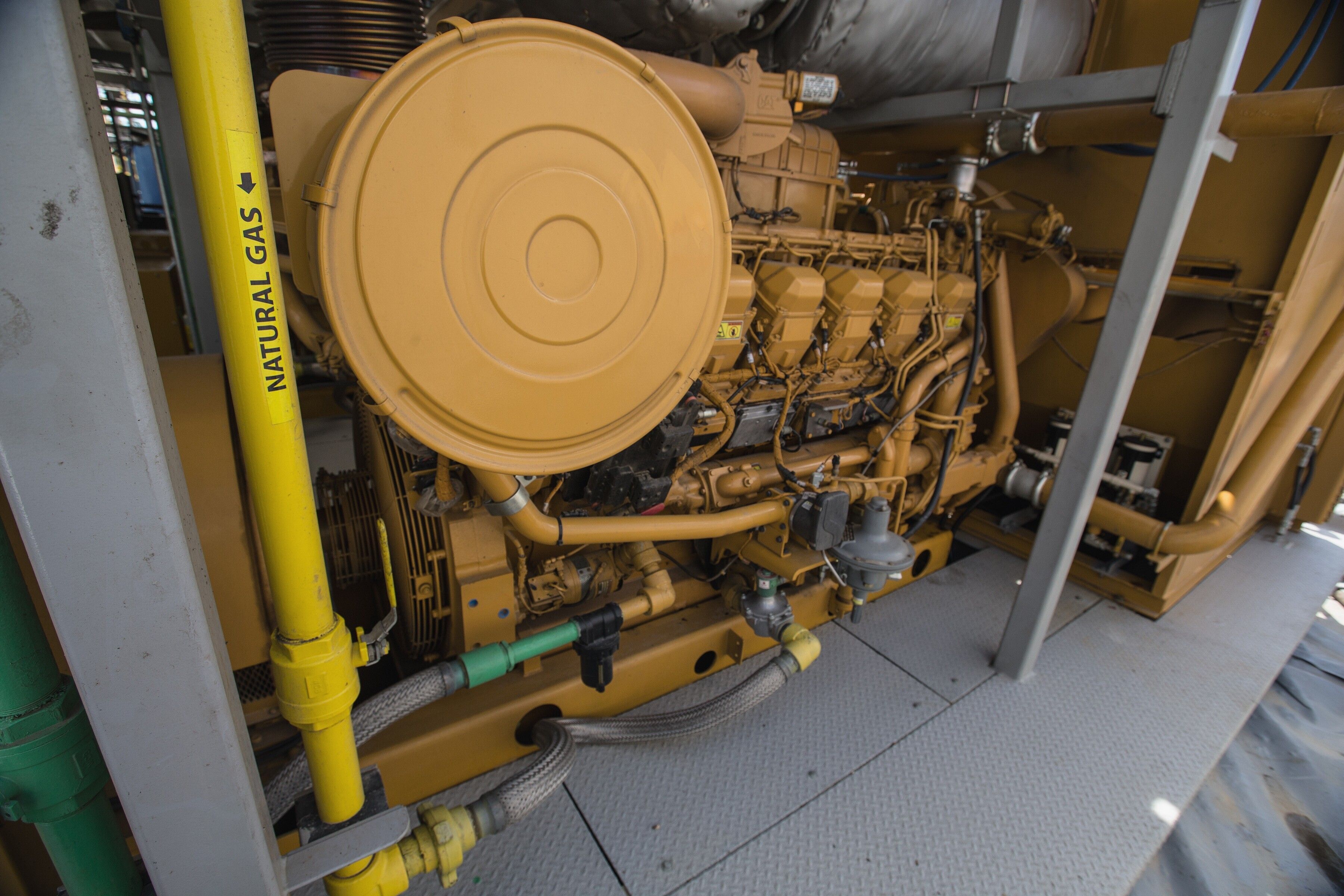

Our Cat engines are known for their high performance and exemplary reliability, making them the first choice for oil and gas applications. Combined with our comprehensive service, we ensure that your engines always operate at their best – even under the toughest conditions.

Wide range of services

Our product range covers power ratings from 50 kW to 16,000 kW. It doesn't matter whether gas, diesel, heavy oil, or crude oil is used as fuel for pumps, compressors, and generators, or whether the application is on land or at sea. We offer the perfect drive solution for maximum success in every application.

Tailored drives

We offer customizable drive systems tailored to the specific requirements of upstream and midstream processes. Depending on the well, flow rate, or environmental conditions, our products are individually configured.

Global availability

Thanks to our global service network, we can ensure fast and reliable support, no matter where your systems are operating. Our specialized technicians are available 24/7 to carry out maintenance and repairs promptly, minimizing downtime to the lowest possible level.

Zeppelin Power Systems Products For Oil & Gas

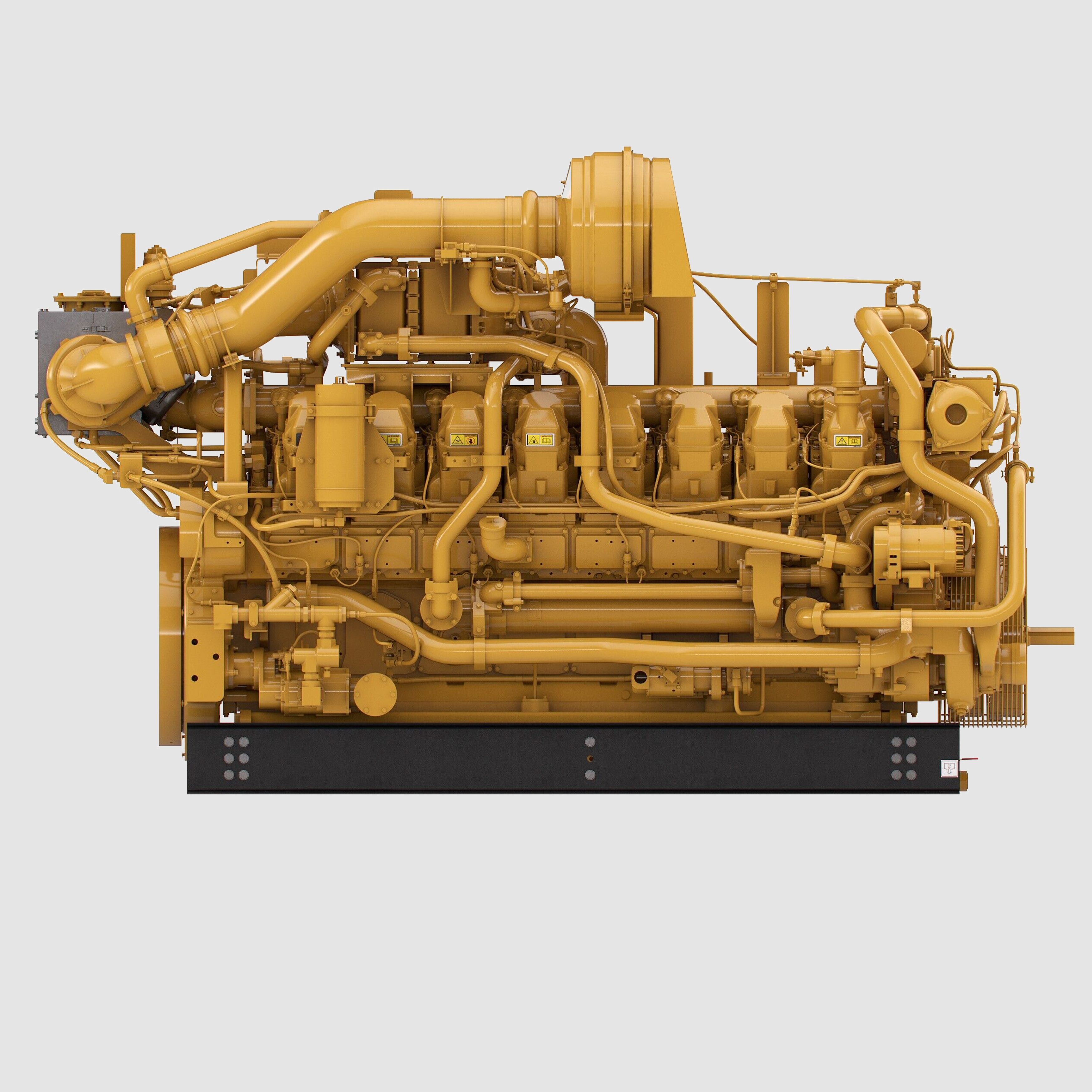

Engines and drives from Caterpillar for your oil and gas applications

Show all Products for Oil & GasSolutions for drilling, production, gas compression, and well service

Oil and gas production encompasses all processes involved in the extraction of crude oil and natural gas from underground reservoirs and is divided into three main phases: upstream (exploration and production), midstream (transport and storage), and downstream (processing and marketing). Zeppelin Power Systems offers powerful drive solutions for the upstream and midstream phases.

Exploration, surveying, and drilling

First, geophysical and geological methods are used to investigate where oil and gas deposits may be located. Once a promising site is found, the drilling process begins. Specialized drilling rigs (drill towers) are set up to create a borehole in deep underground layers. After drilling is complete, the borehole is lined with steel pipes and sealed with cement to ensure stability. A wellhead is installed to enable pressure control and to establish the connection between the borehole and the production facilities. Drilling rigs and cementing plants require a lot of energy, which can be provided by our powerful Cat drilling drives. We can meet any requirement and deliver the drive suited to all conditions.

Extraction of the raw material

After drilling, the production phase begins, and the actual extraction of oil or gas starts. Initially, production is driven by the natural pressure of the reservoir, causing the oil to flow to the surface. When the pressure decreases, artificial lifting methods such as well stimulation with pumps and fracking – the injection of water, gas, or chemicals – are used to maintain the production flow. For gas fields, the gas is often transported directly via pipelines. Various pumping and compressor systems are employed for this purpose. In low-pressure oil fields, deep pumps are used to bring the oil to the surface. A commonly used pump is the horsehead pump (also known as a beam pump), which uses a mechanical lever to lift oil from deep reservoirs. For natural gas reservoirs, compressors are used to compress the gas under high pressure, preparing it for transport through pipelines. Our tailored drives also play a crucial role here, maintaining the efficiency of the extraction processes.

Well maintenance: Stimulation, repair, cleaning

After drilling and during production, well maintenance is crucial to ensure the long-term productivity of the reservoir. This includes stimulation techniques such as hydraulic fracturing to improve the flow of oil and gas, as well as regular cleaning and repair measures to remove blockages or deposits in the wellbore. We provide specifically tailored drive solutions that enable smooth execution of well maintenance, thus maintaining efficiency and production performance over the long term.

Technical datasheets – Diesel gensets

Planning

- Consulting

- Concept Development

- Project Engineering

Engineering

- Electrical & Installation Planning

- Process Technology

- CAD-based Planning

Project Management

- Site Management

- Technical Procurement

- Quality Assurance

Plant Construction

- Electrical Installation

- Assembly

- Commissioning and Test Run

Service

- Maintenance

- Routine Servicing

- Troubleshooting Service

Zeppelin Power Systems industries

Tailored drive solutions for FPSO, fracking, and more

We offer comprehensive drive and energy system solutions for a variety of industry applications. Our custom Cat engines and generators support FPSO units, fracking trucks, mobile drilling rigs, and geothermal drilling with maximum efficiency and reliability. For demanding applications such as CO₂ injection and offshore wind farms, we provide powerful solutions to ensure smooth and environmentally friendly operations. Even in wireline and slickline services, our systems provide precise control and reliable operation under extreme conditions.

Zeppelin Power Systems Resources for Oil & Gas

Brochures available for Download

Show all Resources for Oil & GasZeppelin Power Systems Portfolio