Reliable drive systems for wireline and slickline services

Optimized technologies for long-lasting and precise operation

Zeppelin Power Systems offers tailored drive and container solutions specifically designed for the requirements of wellbore cleaning with wireline. The powerful well service drives from Cat are integrated into our flexible container solutions for use onshore or on offshore drilling rigs. We ensure that wellbore cleaning is carried out efficiently with slickline services, and optionally, can be monitored via wireline services. Our years of experience allow us to support you in the successful implementation of your projects.

Planning

- Consulting

- Concept Development

- Project Engineering

Engineering

- Electrical & Installation Planning

- Process Technology

- CAD-based Planning

Project Management

- Site Management

- Technical Procurement

- Quality Assurance

Plant Construction

- Electrical Installation

- Assembly

- Commissioning and Test Run

Service

- Maintenance

- Routine Servicing

- Troubleshooting Service

Zeppelin Power Systems Solutions for Oil & Gas

Solutions for slicklines and wirelines

Show all Solutions for Oil & GasOur tailored solutions are designed for continuous operation under extreme conditions, offering optimized performance for precise cleaning operations. With our extensive experience, we support you in making your wellbore operations more efficient.

Wellbore Cleaning

Slickline and wireline services, as wireline technologies, are part of the mechanical wellbore cleaning process. We support you with our comprehensive drive solutions for wellbore cleaning.

Container Solutions

Our robust containers enable the mobility of the system. Benefit from flexible readiness and safe handling, even under extreme conditions.

Key benefits for your organization

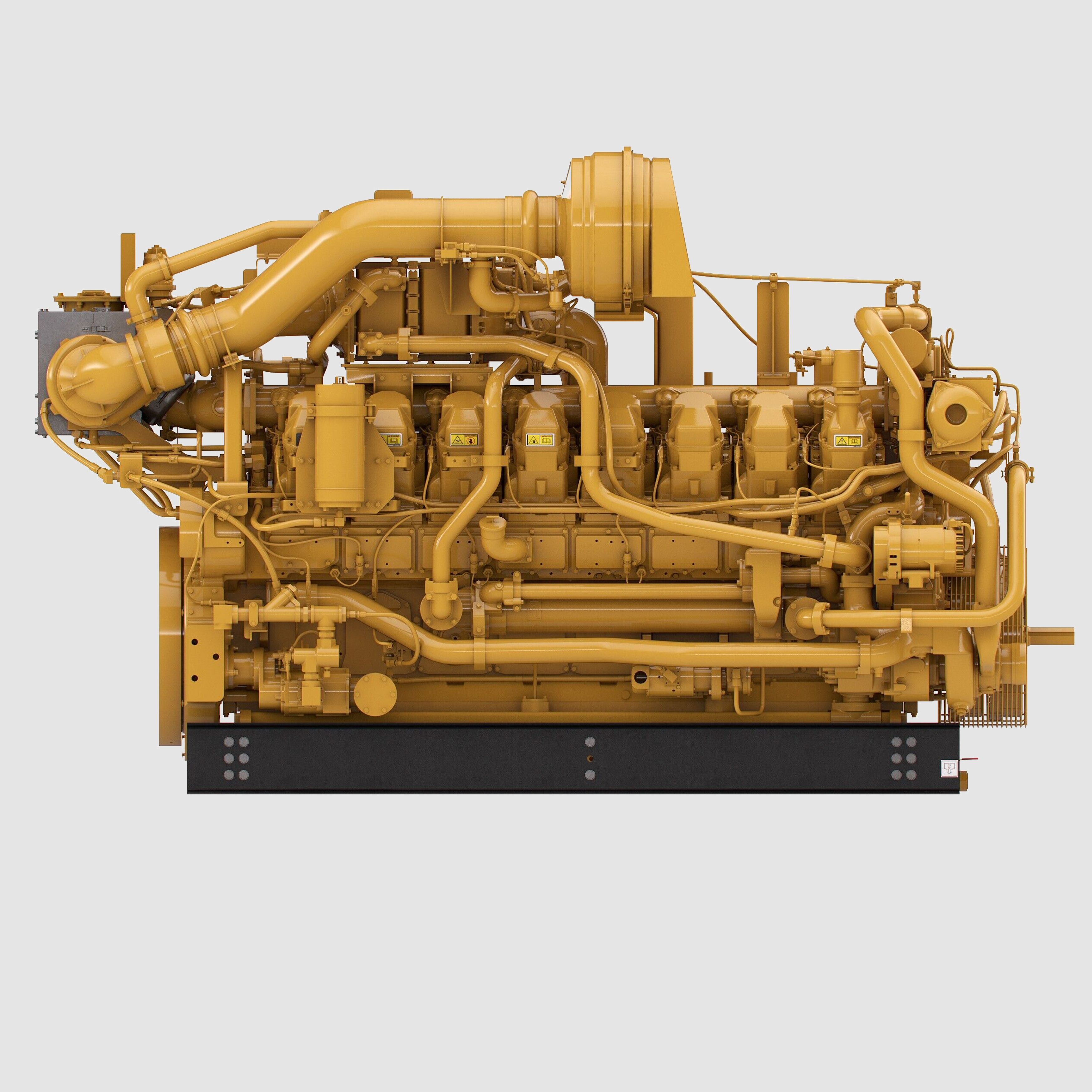

Robust Cat engines and drives

Zeppelin Power Systems provides resilient and reliable Cat engines specifically designed for the use of slickline and wireline services. These engines stand out for their high efficiency and durability, even under extreme conditions. They ensure the smooth operation of powerful drums and other essential systems that are crucial for these services.

Tailored container solutions

Our container solutions provide slickline and wireline service providers with the ability to securely, flexibly, and compactly store their drive systems. These containers protect the equipment from environmental influences while enabling easy maintenance and efficient transport. The containers can be customized to meet the specific requirements of wellbore cleaning.

Reliable service and maintenance

We provide a global service network that ensures fast support and preventive maintenance solutions for equipment. This reduces downtime and helps optimize operational time and efficiency. Particularly in the oil and gas industry, where unplanned shutdowns can be costly, this service offers a clear advantage.

Extensive expertise and know-how

We are your experienced partner for tailored drive solutions for wirelines and slicklines. With decades of experience and extensive expertise in the development and maintenance of high-performance systems, we are here to support you reliably and competently.

Zeppelin Power Systems Portfolio

Weiterführende Themen aus dem Zeppelin Power Systems Portfolio

Our precisely controlled drives and drums power the slickline and wireline cables to ensure efficient cleaning and monitoring of wellbores. The deeper the well, the more powerful the drives need to be. Therefore, we offer engines in a power range from 54 kW to 96 kW.

Engine technology that stands for efficiency and reliability

With a continuously variable hydraulic drive, the Cat engines offer the highest efficiency and reliability for every application. The movable roofs over the winch area allow for an unobstructed view of the operations at all times, enhancing precision and safety. Additionally, parallel operating electrical and hydraulic backup systems ensure the highest safety standards and minimize the risk of failures. The robust construction of our systems is specifically designed for challenging operating environments and withstands the most demanding conditions. The user-friendly pressure control panel, with selectable functions, ensures intuitive operation and maintenance – all CE compliant.

With this technology, you can rely on hassle-free maintenance and smooth operation.

Experience the power of our high-performance engines for yourself.

Zeppelin Power Systems Solutions for Oil & Gas

Tailored containers protect the drives for wirelines and slicklines

Our specially developed container solutions provide a safe and mobile environment for slickline and wireline drives. The containers are robustly constructed and offer space for all essential drive components, tools, and controls. They protect the sensitive equipment from extreme weather conditions and reduce exposure to dust, moisture, and high temperatures, ensuring that the systems operate reliably and safely at all times.

Explosion protection

To ensure safe operation in explosive atmospheres, we also offer ATEX-certified containers. Special pressure-resistant enclosures and explosion-proof components minimize the risk of ignition sources, ensuring maximum safety even in sensitive environments.

Lightweight construction and modularity

Our container solutions are designed to be lightweight enough to be transported by helicopter – saving costs and increasing flexibility in placement. With lightweight construction, the entire system within a container can be reduced to a maximum of 1.5 tons, allowing for safe transport between offshore platforms. The modular design of the containers allows for adaptation to various equipment and tools, making them ideal for changing requirements and deployment locations.

Would you like more information? We are happy to assist you.

Service experts for the oil and gas industry

Reliable service for your drive systems

Reliable systems need reliable service. Our comprehensive service concept covers all aspects of the lifecycle: preventive maintenance, emergency readiness, spare parts management, and technical optimization and retrofits. Our experts support you with expert advice and hands-on training. With digital monitoring solutions and predictive maintenance, we maximize the availability of your drive systems and minimize unplanned downtime.

The use of slickline and wireline in wellbore maintenance

Slickline and wireline services play a central role in well services, as they fulfill important functions for monitoring, maintaining, and optimizing wellbores.

Slickline is used for routine well interventions to maintain efficiency and productivity. It uses a mechanical wire to lower and retrieve tools into the wellbore. These tools are crucial for removing deposits and contaminants, as well as performing maintenance and repair work. Slicklines enable quick and precise interventions in the wellbore, as they do not require an electrical connection. Since the wire is mechanical, operating costs are typically lower than those of electrical systems.

Wireline services utilize a cable with integrated sensors, allowing precise measurements and real-time data recording in the wellbore. The collected data (well logging) such as pressure, temperature, and the condition of surrounding rock formations provide insights into the well's status and are critical for accurate investigations and deeper analysis.

An alternative to wireline is coiled tubing services, which use a continuous steel pipe delivered on a large reel. This technology enables the pumping of chemicals, circulating fluids, conducting drilling operations, and transporting tools into highly deviated or horizontal wells.

By combining slickline and wireline services, operators gain a comprehensive overview of the wellbore’s condition, perform regular maintenance, and carry out repairs efficiently. Both technologies are essential for maximizing the lifespan of wellbores and optimizing their production.

Zeppelin Power Systems Solutions for Oil & Gas

Your specialist for drive technology in the oil and gas industry

Show all Solutions for Oil & GasZeppelin Power Systems Products For Oil & Gas

Reliable products for slickline and wireline applications

Show all Products for Oil & GasZeppelin Power Systems Resources for Oil & Gas

Brochures available for Download

Show all Resources for Oil & GasZeppelin Power Systems Portfolio